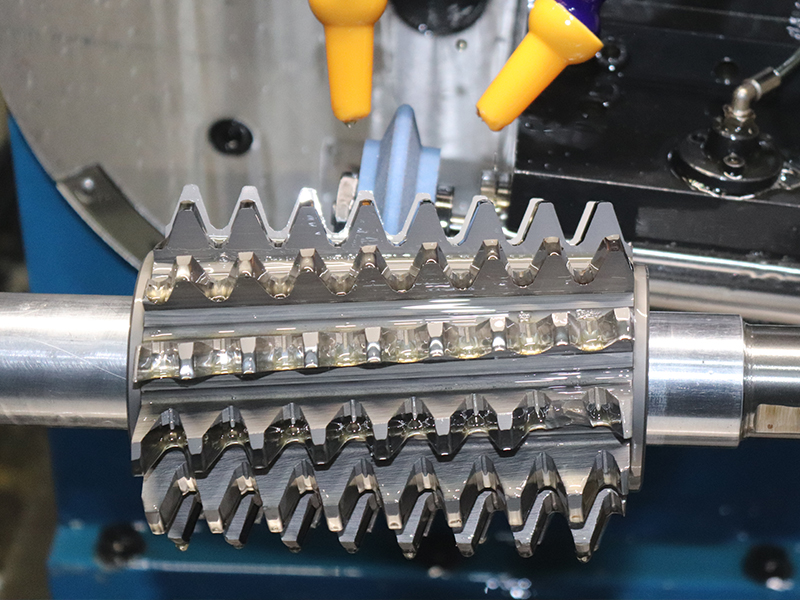

Hobbing can be termed as the a machining process for gear cutting, cutting splines, and cutting sprockets on a hobbing machine, which is a unique kind of processing machine. The teeth or splines of the apparatus dynamically take the fabric by a progression of cuts made by a cutting instrument called a hob. Strong carbide gear hobs may be utilized in shell configuration to chop gears with or without coolant, and are accessible in shell style with keyway or end drives, and different shank plans to suit most hobbing machines. It ought to be produced following explicit steps and features. The cutting performance of gear hobbing is high, with the goal that particularly exceptionally thick gears may be created in an exceedingly moderately brief timeframe. Nonetheless, this cycle cannot be utilized to make interior gears. For this reason, as an example, gear shaping and molding are often utilized.

Hobbing can be termed as the a machining process for gear cutting, cutting splines, and cutting sprockets on a hobbing machine, which is a unique kind of processing machine. The teeth or splines of the apparatus dynamically take the fabric by a progression of cuts made by a cutting instrument called a hob. Strong carbide gear hobs may be utilized in shell configuration to chop gears with or without coolant, and are accessible in shell style with keyway or end drives, and different shank plans to suit most hobbing machines. It ought to be produced following explicit steps and features. The cutting performance of gear hobbing is high, with the goal that particularly exceptionally thick gears may be created in an exceedingly moderately brief timeframe. Nonetheless, this cycle cannot be utilized to make interior gears. For this reason, as an example, gear shaping and molding are often utilized.

One can find top of the gear hob manufacturers in India. Contingent upon the type of gears needed to be created (spike, helical, cycloid, sprocket, and so on), it’s particular to decide on a choice with the actual reasonably gear hob accustomed fabricate it. And afterward, there comes an unavoidable issue as of where to buy the simplest gear hobs or gear cutting devices for one’s need. The most things to seem at with the gear hobs providers are their organization profile. observe everything significant about the provider as of when was this firm settled, do they need any affirmations, what’s their work cycle, do they offer any discounts on the off chance that customers don’t seem to be pleased with their items, etc. Some important points to be noted about the gear hobs are presented below:

- Better performance- Gear riggings are utilized to maneuver movement and force between machine segments in mechanical gadgets. Contingent upon the structure and development of the gear pair utilized, gears can alter the course of development additionally as speed up or force. Gears are utilized in huge amounts of mechanical gadgets Contingent upon the structure and development of the gear pair utilized, gears can alter the course of development additionally as speed up or force. Gears are utilized in huge amounts of mechanical gadgets.

- Reduced human effort- They are doing some significant positions, however generally significant, they provide an apparatus decrease in mechanized hardware. This can be key because, frequently, a bit engine turning exceptionally quick can give enough capacity to a gadget, however insufficient force. Each cutting tooth of the hob is given alleviation at its back to empower leeway. The cross-area of the very tooth over the helix sounds like that of the rack teeth as appeared within the figure.They are doing some significant positions, however generally significant, they provide an apparatus decrease in mechanized hardware. This can be key because, frequently, a bit engine turning exceptionally quick can give enough capacity to a gadget, however insufficient force. Each cutting tooth of the hob is given alleviation at its back to empower leeway. The cross-area of the very tooth over the helix sounds like that of the rack teeth as appeared within the figure.

Apart from the above mentioned, another sorts of gear hobs are straight spline hobs, spur, and helical hobs, roller chain sprocket hobs, etc. the purpose that’s to be kept in mind before pursuing a supplier of the identical is that the cost and quality relationship the supplier if offering. Since there are many manufacturers and suppliers of the identical present within the market, one includes a range of other choices. A client must carefully investigate the credibility and customer reviews as well at the time of finding the gear hob manufacturers in India.